Blast Cabinets

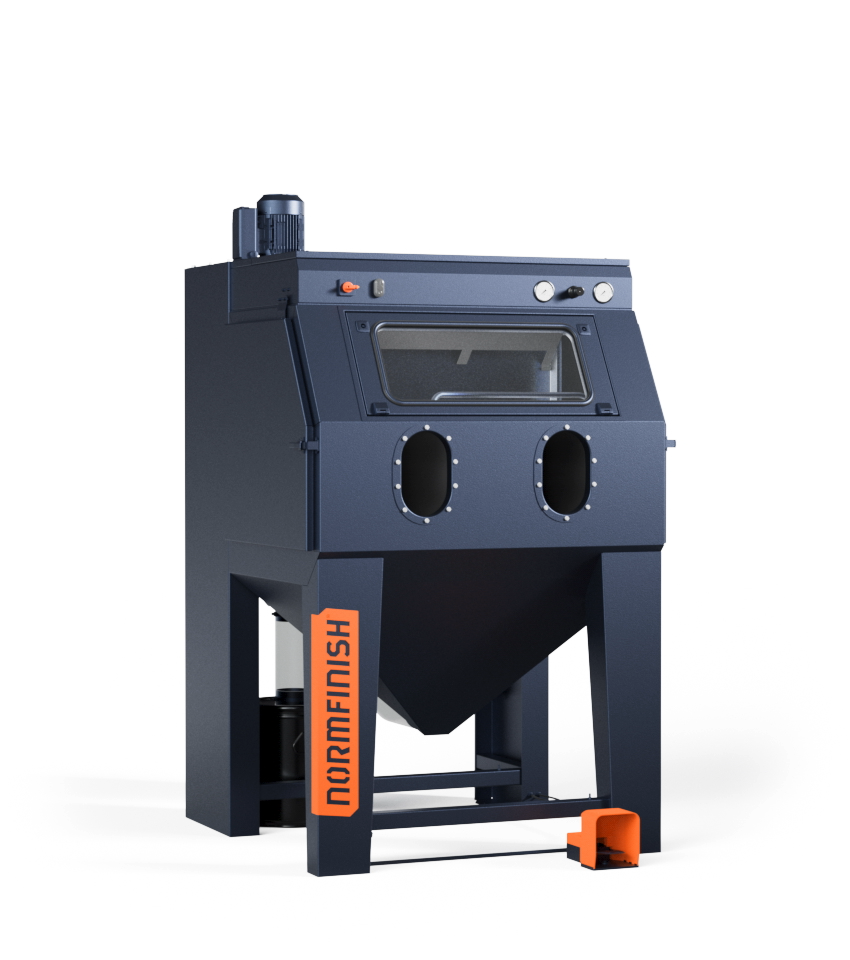

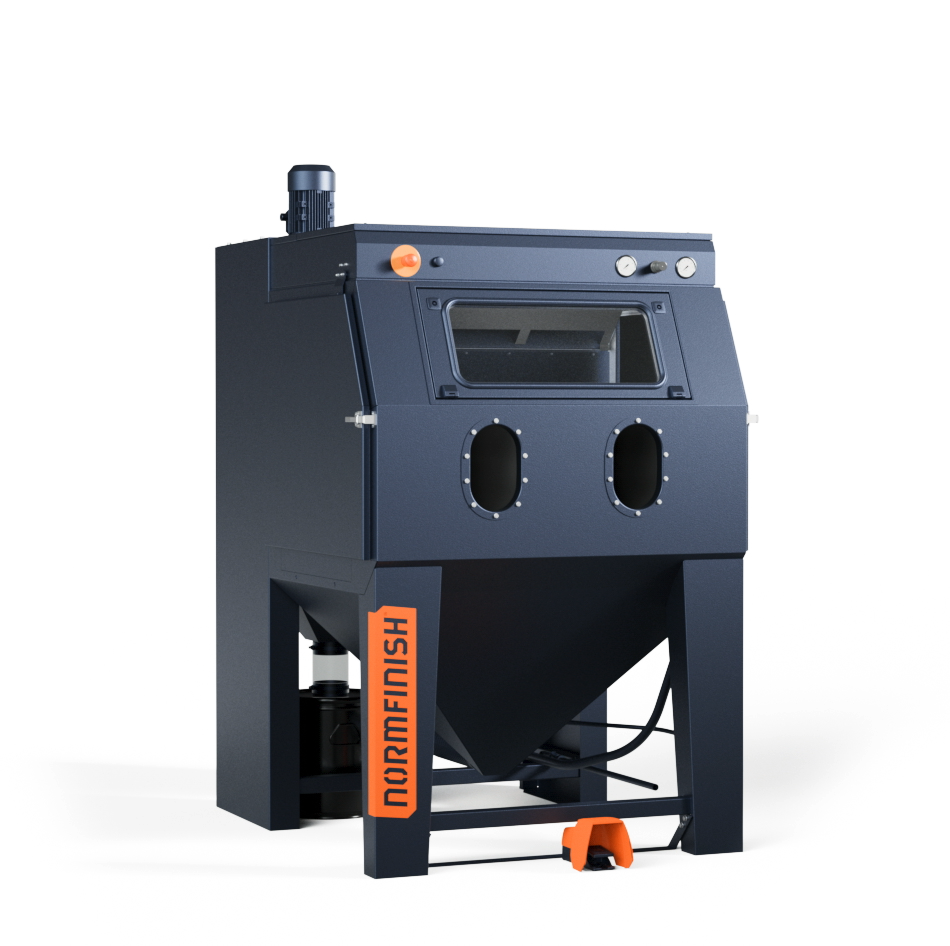

Normfinish blast cabinets are intended for frequent blasters with high demands on the blasting results, clear view, user convenience, safety and the environment. All components are assembled, according to ISO-certification, to create a compact turn-key unit. These machines are available in both dry and wet blasting.

We also offer an economy range, the Mistral series, basic blast cabinets based on the technique of Normfinish.

Advantages of Normfinish blast cabinets:

High level of finish, durability and safety

During the development and production of the Normfinish blasting booths, in addition to the blasting technology, our Engineering Department has paid great attention to the aspects of durability and safety. Some examples are the highly wear-resistant Linatex lining on the inside of the booths, the safety sensors on the doors and the flexible oval arm pass-through. What also sets our blast cabinets apart are the ergonomic and compact design and limited dust emissions. When using the optional HEPA filter, dust emission is even limited to just 0.1 mg/Nm³. In addition to optimal dust extraction, the Normfinish blast rooms are equipped with cyclone. This ensures the perfect separation of the blasting dust, resulting in good visibility during the blasting process.

ATEX certified blast rooms

In order to serve the market to its full extent, we also supply blast cabinets equipped with a so-called ATEX certificate. The term ATEX covers all situations where there is a risk of gas and dust explosion. The abbreviation ATEX comes from the French words ATmosphere EXplosible from the European directives of explosion safety. Companies and organizations that work in explosive environments must take measures so that employees can perform their work safely. ATEX standards or directives have been drawn up for this purpose, which the special versions of our blast rooms comply with.

Blast cabinet options for demanding users

For both (pressure) DP, (injector) DI blasting booths and automated custom blasting systems, Normfinish offers numerous parts and accessories. These include stationary rotary tables, a rail transport system, blast gun holders, lighting and options for programming and monitoring the blasting process. In addition, associated accessories such as nozzles, blast hoses, blast gloves, etc. are also available from us.

Normfinish blast rooms let every professional blast

Are you looking for a suitable solution for injector blasting, pressure blasting, automated or mobile blasting of your products? Then check out our range of blasting booths and accessories or contact us for advice or to work out a fully customized (mobile) blasting unit or blasting hall for you. Normfinish makes every professional shine!

Our blast cabinet product range

The Normfinish blasting cabinets range consists of cabinets for dry blasting and for wet blasting.

Within dry blasting we offer injector booths and pressure blasting booths. Want to know more about the different working principles? In this article we explain it to you completely.

In addition, we also offer blast rooms, specially designed for finishing 3D printed plastic or metal parts.

Are you looking for a professional blast cabinet and have high demands on the blasting process?

Normfinish blast rooms offer you the best results. For less frequent blasting a mistral series blast cabinet may be of interest to you, a series of basic blast cabinets with all the basic features based on Normfinish technology.

Specific wishes for your blast cabinet?

Do you have specific requirements for a blast cabinet, e.g. size of the product to be blasted, feed, frequency, material? We develop automated blast cabinets with different operating principles. Our in-house Engineering Department develops specific solutions for specific customer requests in cooperation with the customer.

Mistral Series

The mistral series blast cabinets from Normfinish are known for a good price/quality ratio and are therefore an economical choice when less is required of the blasting process.